Estimated reading time: 10 mins

In an era where the fusion of functionality and artistry in furniture is increasingly celebrated, epoxy resin tables stand as a testament to this modern synthesis. This article delves into the world of epoxy resin tables, a realm where chemistry meets craftsmanship to create pieces of functional art. Epoxy resin, a thermosetting polymer known for its durability and versatility, has found a unique niche in the domain of furniture making. Its ability to encapsulate objects and colors, combined with its robustness, has allowed for the creation of tables that are not just pieces of furniture, but expressions of creativity and style.

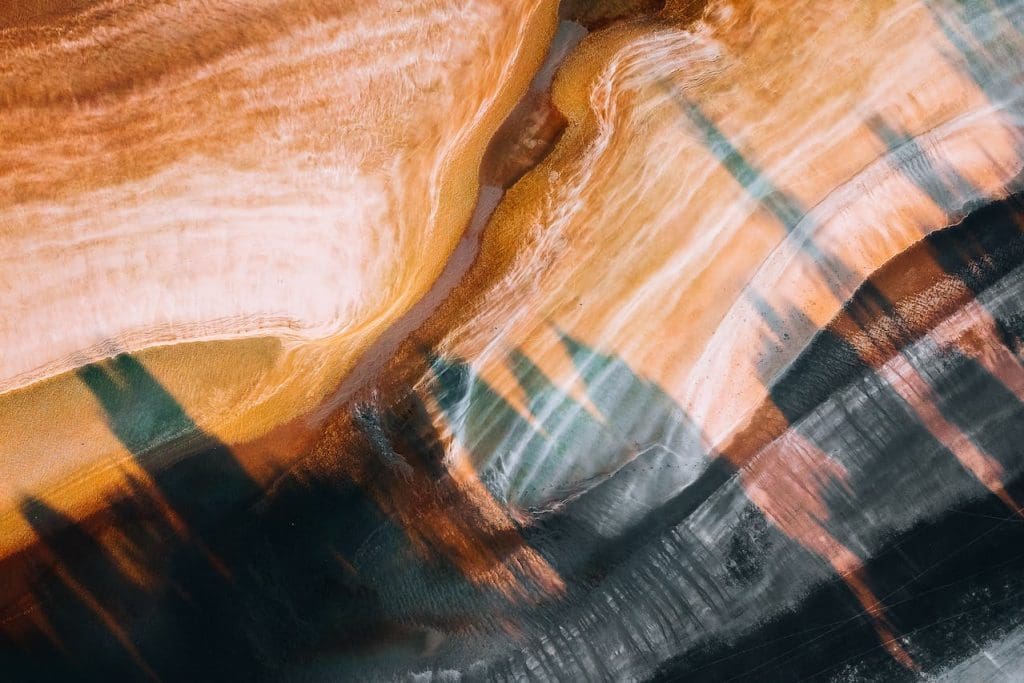

These tables are more than just surfaces to rest items on; they are the convergence points of practicality and aesthetic appeal. The resin’s clear or tinted composition can be manipulated into stunning designs, ranging from mimicking ocean waves to embedding objects like leaves, stones, or even LED lights, resulting in truly bespoke pieces. This article aims to provide an analytical insight into how epoxy resin tables are reshaping the landscape of modern furniture design, touching upon their historical evolution, manufacturing process, and the implications they hold in contemporary design trends. As we journey through the intricate world of these captivating tables, we uncover the science and artistry that makes them a focal point in both residential and commercial spaces.

The Rise of the Epoxy Resin Table in Contemporary Design

The ascent of the epoxy resin table in contemporary interior design is a fascinating interplay of aesthetic innovation and functional prowess. This popularity can be attributed to several key factors that resonate with modern design sensibilities and practical requirements.

Firstly, the aesthetic appeal of epoxy resin tables is unparalleled. They offer a unique blend of natural beauty and artistic creativity, making each piece a one-of-a-kind work of art. The ability of epoxy resin to encapsulate various objects and colors allows for limitless design possibilities. From embedding natural elements like wood, stones, and shells to creating mesmerizing color patterns and effects, these tables can be tailored to suit any interior theme, from rustic to ultra-modern. The depth and clarity of the resin also add a dimensional quality, often giving the impression of a liquid or glass-like surface that is both striking and elegant.

Moreover, the rise of individualism in interior design has fueled the demand for bespoke furniture. Epoxy resin tables cater to this trend perfectly, as each table can be customized to the client’s specifications, ensuring a personal touch and a unique aesthetic. Designers and artists have embraced this medium to express their creativity, leading to an array of stunning and innovative designs that push the boundaries of traditional furniture making.

Functionally, epoxy resin tables offer several advantages. Their durability is a significant factor; these tables are resistant to scratches, heat, and moisture, making them ideal for both residential and commercial settings. This longevity and resilience make them a practical investment for spaces that see heavy use, like dining areas and offices. Additionally, the non-porous nature of epoxy resin makes these tables easy to clean and maintain, an essential consideration in today’s fast-paced lifestyle.

The versatility of epoxy resin also contributes to its popularity. It can be used to create not just flat table surfaces but also intricate designs and shapes. This flexibility has opened up new avenues in furniture design, allowing for the integration of epoxy resin with various materials like wood, metal, and glass, creating pieces that are as much sculptures as they are functional items.

Furthermore, the transparency and reflective quality of epoxy resin can enhance the sense of space in a room, making it particularly appealing for smaller spaces or areas that require a light and airy feel. The material’s ability to refract and reflect light adds a dynamic element to the space, changing throughout the day with the natural light.

In addition to aesthetics and functionality, there is also an emotional aspect to the rise of epoxy resin tables. In a world increasingly dominated by mass-produced, impersonal items, the handcrafted, bespoke nature of these tables offers a connection to the artisan and the creative process. This emotional resonance, combined with the environmental consciousness of using sustainable materials like reclaimed wood, resonates with contemporary values.

In conclusion, the rise of epoxy resin tables in contemporary design is a multifaceted phenomenon. It is driven by the material’s unique aesthetic qualities, its functional benefits, and its ability to align with the values and preferences of modern consumers. These tables are not just furniture pieces but are emblematic of the interplay between art and utility, individuality and sustainability, in contemporary interior design.

Manufacturing Process and Material Science Behind Epoxy Resin Tables

The creation of an epoxy resin table is a blend of art and science, involving precise material selection and a meticulous manufacturing process. Understanding the properties of epoxy resin and the steps involved in crafting these tables is key to appreciating their value and uniqueness.

Material Science of Epoxy Resin:

Epoxy resin is a thermosetting polymer, known for its strong adhesive qualities, high mechanical strength, and durability. It is composed of two main components: the resin and the hardener. When mixed, these components undergo a chemical reaction called curing, transforming from a liquid into a solid, thermoset plastic. This process is exothermic, meaning it releases heat.

Key properties of epoxy resin that make it ideal for table making include:

- Transparency and Color Versatility: Epoxy resin is naturally clear, which allows for the addition of pigments to create a wide range of colors and effects.

- Adhesion: Its ability to bond with various materials, such as wood, metal, and glass, makes it versatile for different design concepts.

- Durability: It is resistant to water, heat, and common household chemicals, making it a practical choice for furniture.

- Flexibility in Design: It can be cast into different shapes and sizes, allowing for customization.

Manufacturing Process:

- Design and Planning: The process begins with a design concept. This includes selecting the materials to be encapsulated in the resin (like wood or objects for aesthetic purposes), determining the shape and size of the table, and planning the color scheme.

- Preparing the Mold: A mold is constructed, often from silicone or a rigid frame with a smooth, non-stick surface. The mold defines the shape and dimensions of the final table.

- Mixing the Resin: Epoxy resin and hardener are mixed in a specific ratio. This ratio is crucial as it determines the curing time and the final properties of the resin. Color pigments or other additives can be mixed at this stage.

- Pouring and Curing: The resin is poured into the mold, often in layers, especially for thicker tables or if objects are being embedded. Each layer must partially cure before the next is added to prevent distortion. The curing process can take several hours to days, depending on the resin’s formula and the table’s thickness.

- Embedding Materials: If materials like wood or decorative objects are part of the design, they are placed into the mold, and resin is poured around them. Careful attention is needed to avoid air bubbles and ensure proper adhesion.

- Demolding and Sanding: Once fully cured, the table is removed from the mold. The surface is then sanded to remove any imperfections and to achieve the desired finish. This can be a labor-intensive process, requiring multiple grades of sandpaper.

- Polishing and Finishing: The table is polished to a high shine, enhancing its clarity and color. Additional coatings or treatments can be applied for UV protection or to achieve different textures.

- Quality Check and Finishing Touches: The final step involves a thorough quality check and any additional finishing touches, such as attaching legs or hardware.

Throughout this process, craftsmanship and attention to detail are paramount. The skill of the artisan in manipulating the resin, understanding the material’s behavior, and bringing the design concept to life, is what makes each epoxy resin table a unique piece of art. The combination of material science and skilled craftsmanship in these tables represents the pinnacle of modern furniture design, marrying form and function in a truly unique way.

Sustainability and Environmental Impact

The use of epoxy resin in furniture making, particularly in the creation of tables, has raised important questions about sustainability and environmental impact. While epoxy resin tables are known for their aesthetic appeal and durability, it’s essential to consider their ecological footprint.

Environmental Impact of Epoxy Resin:

- Production Process: The production of epoxy resins involves petrochemicals, which means it is reliant on fossil fuels. The extraction and processing of these materials have significant environmental impacts, including greenhouse gas emissions and resource depletion.

- Non-Biodegradability: Once cured, epoxy resin is a plastic material that is not biodegradable. At the end of its lifespan, a resin-based product can contribute to plastic pollution if not disposed of properly.

- Toxicity and Health Concerns: The manufacturing and curing processes of epoxy resins can release volatile organic compounds (VOCs) and other potentially harmful chemicals. These pose health risks to artisans during production and can have environmental impacts if not managed correctly.

Sustainability Efforts and Eco-Friendly Alternatives:

- Use of Recycled or Reclaimed Materials: One way to enhance the sustainability of epoxy resin tables is by incorporating recycled or reclaimed materials, such as wood or metal. This approach reduces waste and lowers the demand for new raw materials.

- Biodegradable Resins: Research and development are underway to produce more eco-friendly resins. Biodegradable resins, though not yet widely available or as robust as conventional epoxy, represent a promising area for sustainable furniture making.

- Reducing Waste in Production: Manufacturers can adopt practices to minimize waste during the production process. This includes recycling excess materials and using more efficient molds and processes.

- Improving Indoor Air Quality: To address the issue of VOCs, manufacturers can develop and use formulations with lower toxic emissions, thus reducing indoor air pollution and making the working environment safer.

- End-of-Life Management: Encouraging responsible disposal and recycling strategies for resin-based furniture is crucial. This can include programs for refurbishing or repurposing the furniture.

- Sustainable Sourcing and Manufacturing Practices: Choosing suppliers who adopt environmentally friendly practices, such as using renewable energy sources and minimizing waste in the production of epoxy resin, can also contribute to sustainability.

- Alternative Materials: Exploring other materials with lower environmental impacts, such as glass, metal, or sustainably sourced wood, can be an alternative for those seeking more environmentally conscious furniture options.

In conclusion, while epoxy resin tables offer unique design possibilities and durability, it is important to balance these benefits with environmental considerations. The furniture industry, artisans, and consumers alike play a role in fostering sustainability by adopting eco-friendly practices, exploring alternative materials, and supporting innovations that reduce the environmental footprint of resin-based furniture.

Conclusion

The exploration of epoxy resin tables in the context of contemporary furniture design reveals a fascinating intersection of artistry, craftsmanship, and innovation. These tables represent more than just a trend; they embody a shift in how we perceive and interact with the objects in our living spaces.

Key insights from this exploration include:

- Material Innovation: Epoxy resin, as a material, offers unique properties like versatility, durability, and aesthetic appeal. Its ability to bond with different materials and to encapsulate various objects and colors has opened new avenues in furniture design.

- Customization and Personal Expression: The rising popularity of epoxy resin tables is heavily tied to the contemporary demand for customization and personalization in interior design. These tables offer a unique opportunity for individuals to express their style and for designers to push the boundaries of traditional furniture making.

- Artistic and Functional Fusion: Epoxy resin tables stand at the crossroads of art and utility. They serve not just as furniture but as conversation pieces, adding a distinctive character to both residential and commercial spaces.

- Sustainability Concerns and Innovations: While there are environmental concerns associated with the use of epoxy resin, the industry’s move towards more sustainable practices and materials is a positive step. The integration of recycled materials and the development of eco-friendly resins are examples of how the sector is evolving in response to ecological considerations.

- Market Trends and Consumer Preferences: The market trends indicate a strong interest in epoxy resin tables, driven by factors such as the desire for durability, the appeal of artisanal craftsmanship, and the trend towards sustainable and multifunctional furniture.

- Diverse Design Potential: The case studies of iconic epoxy resin table designs demonstrate the vast potential of this medium. From river and ocean designs to embedded objects and glow-in-the-dark features, these tables are as diverse as the imagination of their creators.

In conclusion, epoxy resin tables are more than a fleeting trend in furniture design; they are a testament to the evolving relationship between form and function, art and utility. They reflect a growing appreciation for handcrafted, bespoke pieces that tell a story and resonate on a personal level. As we continue to explore the possibilities of materials and design, epoxy resin tables stand as a symbol of the creativity and innovation that defines the future of furniture craftsmanship.